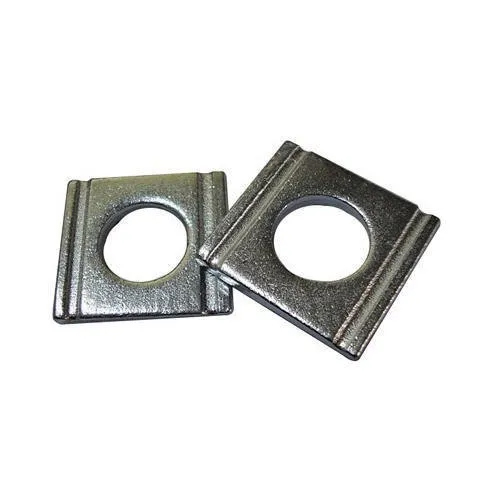

Tapered Washers are specialized washers designed with a sloping or angled surface, typically used in situations where a bolt or fastener is being installed on a surface that is not perpendicular to the axis of the bolt. The tapered shape compensates for the angle, ensuring that the bolt or nut applies even pressure and maintains proper alignment during fastening.

Key Features of Tapered Washers:

- Material:

- High-Strength Steel: Tapered washers are commonly made from durable materials such as steel, stainless steel, or hardened alloys to withstand high loads and stresses.

- Corrosion Resistance: They are often treated with coatings like zinc, galvanized, or made from corrosion-resistant materials to prevent rust in outdoor or harsh environments.

- Design:

- Tapered Shape: One side of the washer is thicker than the other, creating a sloping or wedge-like shape. This design helps to compensate for angled surfaces, allowing the bolt or fastener to sit perpendicular to the load-bearing surface.

- Flat or Beveled Surface: The surface of the washer may be flat or slightly beveled, depending on the specific application and the angle it is compensating for.

- Applications:

- Sloped Surfaces: Tapered washers are primarily used when fastening bolts or nuts on sloped or angled surfaces, such as structural beams, I-beams, or rail components.

- Railway Systems: In railway construction, tapered washers are used to ensure bolts remain securely fastened on angled surfaces like rail track clips and joints.

- Structural Engineering: Tapered washers are common in structural engineering to provide proper load distribution on bolts installed in girders, frames, or other angled components.

- Woodworking: In timber construction, especially with bolts running through beams or joists at an angle, tapered washers ensure proper clamping force.

- Installation:

- Correct Placement: Tapered washers must be installed with the thick end facing the higher part of the surface and the thinner end toward the lower part. This ensures the bolt or nut is aligned properly.

- Securing: Once placed correctly, the fastener (bolt or nut) is tightened as usual. The washer’s taper helps distribute the load evenly across the fastened surface, preventing slippage or uneven wear.

- Maintenance:

- Regular Inspections: Tapered washers, like other fasteners, should be inspected for signs of wear, corrosion, or loosening, particularly in environments subject to vibrations or dynamic loads.

- Replacement: Damaged or worn washers should be replaced promptly to ensure the continued integrity of the joint or fastened assembly.