A guide rod in railway applications is a structural component designed to guide and support the movement of mechanical systems, ensuring precise alignment and stability. Guide rods are commonly used in various railway systems such as track switching mechanisms, signal control, and braking systems. They help ensure smooth, accurate, and controlled movement of components that must operate in specific directions or along predefined paths.

Here’s an overview of the guide rod and its significance in railway operations:

Key Features of Guide Rods:

Functionality:

- Guiding Mechanical Movement: The primary function of a guide rod is to ensure that moving parts of a mechanical system travel along a straight, controlled path without deviation. In railway systems, this might be used to control the movement of switch blades, signal arms, or other critical components.

- Stabilizing Force: Guide rods offer stability by preventing lateral movement or misalignment during operations. This is particularly important for ensuring reliable switching and signaling in railway tracks.

Material:

- High-Strength Materials: Guide rods are typically made from durable materials such as steel, stainless steel, or hardened alloys to withstand the heavy loads, stress, and environmental conditions in railway settings.

- Corrosion Resistance: For outdoor use, guide rods are often treated with protective coatings like zinc plating or galvanized finishes to resist corrosion, especially in areas exposed to rain, moisture, or extreme temperatures.

Design:

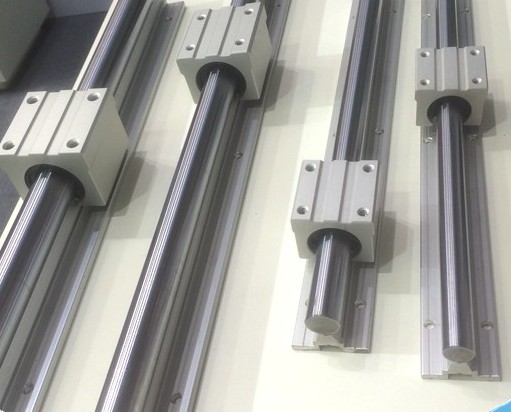

- Cylindrical Shape: Guide rods generally have a cylindrical design, providing a smooth surface for guiding mechanisms or parts that slide along them. Their diameter and length vary based on the system’s specific requirements.

- Precision Engineering: Guide rods are machined to high tolerances to ensure accurate movement and prevent any unwanted play or wobble, which is essential for maintaining operational precision.

Installation:

- Fixed in Place: Guide rods are usually installed securely in a fixed position, aligned along the direction of movement they are designed to control. This ensures that they effectively guide the attached mechanical components.

- Paired with Bearings or Sleeves: In many systems, guide rods are paired with linear bearings or sleeves, which move smoothly along the rod, reducing friction and ensuring accurate alignment.